Metal

Product Awards

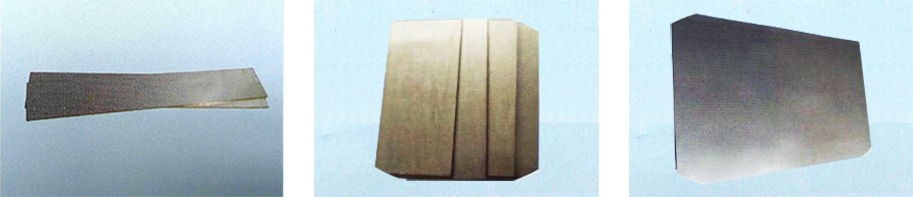

[ The Rolled Plates/Sheets ]

- · Molybdenum and Their Alloys

- Designation: Mo1, Mo2, TZM, Mo3G, JMo1

- Technical Requirements: GB3876-83, GB3877-83, ASTM B386-91

- Applications: Being widely used in electron, electric light source industries, heating bodies and heat shields of electro-vacuum, molybdenum boats, molybdenum crucibles and others. Please check table 1 for the designation, condition, specification of molybdenum products and table 2 about the dimension tolerance.

#Table 1

| Designation | Process | Delivery Condition | Size(mm) | ||

| Thickness | Width | length | |||

| Mo1 | P/M | Cold Rolled(Y) | 0.10~0.70 | 50~480 | 100~1500 |

| Stress relisf anneaeling(M) | 0.10~0.70 | 50~480 | 100~1500 | ||

| JMo1 | Hot Rolled(Y) | >0.7~30 | 50~480 | >100 | |

| Cold Rolled Stress relisf anneaeling(M) | 0.10~0.70 | 50~480 | 50~200 | ||

| Designation | Process | Delivery Condition | Size(mm) | ||

| Thickness | Width | length | |||

| Mo1 | P/M | Cold Rolled(Y) | 0.10~0.70 | 50~480 | 100~1500 |

| Stress relisf anneaeling(M) | 0.10~0.70 | 50~480 | 100~1500 | ||

| JMo1 | Hot Rolled(Y) | >0.7~30 | 50~480 | >100 | |

| Cold Rolled Stress relisf anneaeling(M) | 0.10~0.70 | 50~480 | 50~200 | ||

#Table 2

| Thickness | Thickness Tolerance | Width Tolerance | Length Tolerance | |

| Grade 1 | Grade 2 | |||

| 0.1~0.15 | 0.01 | ±0.01 | ±2 | ±5 |

| >0.15~0.30 | ±0.02 | ±0.02 | ±2 | ±5 |

| >0.30~0.50 | ±0.03 | ±0.03 | ±2 | ±5 |

| >0.50~0.70 | ±0.04 | ±0.04 | ±3 | ±5 |

| >0.70~1.0 | ±0.05 | ±0.05 | ±3 | ±5 |

| >1.0~2.0 | ±0.06 | ±0.06 | ±5 | ±5 |

| >2.0~3.0 | ±0.08 | ±0.08 | ±5 | ±5 |

| >3.0~4.0 | ±0.10 | ±0.20 | ±5 | ±5 |

| >4.0~5.0 | ±0.12 | ±0.32 | ±5 | ±5 |

| Thickness | Thickness Tolerance | Width Tolerance | Length Tolerance | |

| Grade 1 | Grade 2 | |||

| 0.1~0.15 | 0.01 | ±0.01 | ±2 | ±5 |

| >0.15~0.30 | ±0.02 | ±0.02 | ±2 | ±5 |

| >0.30~0.50 | ±0.03 | ±0.03 | ±2 | ±5 |

| >0.50~0.70 | ±0.04 | ±0.04 | ±3 | ±5 |

| >0.70~1.0 | ±0.05 | ±0.05 | ±3 | ±5 |

| >1.0~2.0 | ±0.06 | ±0.06 | ±5 | ±5 |

| >2.0~3.0 | ±0.08 | ±0.08 | ±5 | ±5 |

| >3.0~4.0 | ±0.10 | ±0.20 | ±5 | ±5 |

| >4.0~5.0 | ±0.12 | ±0.32 | ±5 | ±5 |

- · Tungsten and Their Alloys

- Designation: W1, W2

- Technical Requirements: GB3875-83, ASTM B760-86

- Applications: Being widely used in tungsten electropolar plates, tungsten boats, tungsten heat shields and heating bodies for electro-vacuum, electric light source, electronics industries and others.

- · Tantalum , Niobium Their Alloys

- Designation: Ta1, Ta2, Nb1, Nb2

- Technical Requirements: GB/T3628-1995, GB3626-83, ASTM B708-92, ASTM B393-89

- Dimension: 0.05~30 x 10~450 x L mm

- Delivery Condition: Annealed (M), Cold rolled(Y)

- · Titanium, Nickel and Their Alloys.

- Designation: Ti1, Ti2, TC4, N4, N6

- Technical Requirements: GB/T3621-94, GB3622-83, GB2054-80,ASTM B265-93, ASTM B162-93

- Dimension: 0.05 x 30 x 10~450 x L mm

- Delivery Condition: Annealed (M), Cold rolled(Y)

- · Zirconium, Hafnium and Their Alloys.

- Designation: Zr1, Zr2, Zr4, Hf

- echnical Requirements: Q/XB1601-96, Q/BS6531-91, ASTM B551-92, ASTM B776-91

- Dimension: 0.10 x 30 x 10~450x L mm

- Delivery Condition: Annealed (M), Cold rolled(Y)